Understanding Injection Molding Machines

Injection molding machines are pivotal in transforming raw plastic into an array of products, from simple household items to complex industrial parts. The efficiency and precision of these machines have propelled them to the forefront of modern manufacturing processes across various industries. As companies strive to enhance production capabilities while cutting costs, electric injection molding machines have emerged as a leading solution. This article explores the fundamentals of injection molding machines, focusing on their key components, types, and the advantages of electric variants, aimed at manufacturers looking to innovate their production lines.

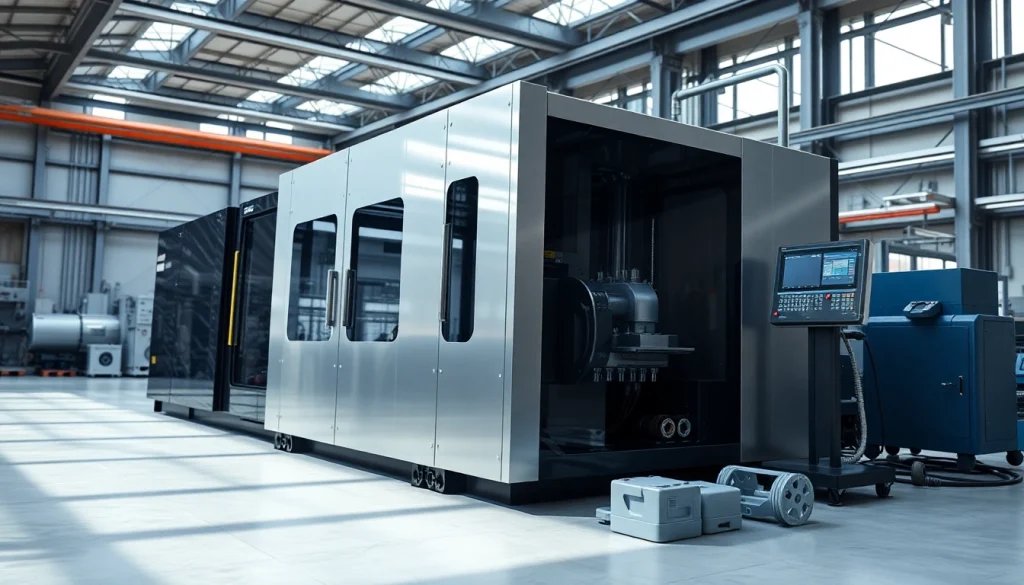

What is an Injection Molding Machine?

An injection molding machine is specialized equipment designed for manufacturing plastic parts through a process known as injection molding. This process involves melting plastic pellets and injecting the molten material into a mold at high pressure. Once cooled, the plastic solidifies, taking the shape of the mold. These machines come in various configurations, each tailored to specific production needs.

Key Components and Their Functions

Understanding the basic components of an injection molding machine is crucial for maximizing production efficiency. The main components include:

- Hopper: This is where raw plastic pellets are fed into the machine.

- Screw: The screw melts the plastic and moves it towards the mold.

- Injection unit: This is responsible for injecting the molten plastic into the mold cavity.

- Clamping unit: This secures the mold during the injection process.

- Control system: This oversees machine operations and monitors parameters for optimal performance.

Types of Injection Molding Machines in Use Today

There are several types of injection molding machines available, each suited for different applications:

- Hydraulic Injection Molding Machines: Operates using hydraulic fluid pressure to move the injection and clamping units.

- Electric Injection Molding Machines: Utilize electric motors for all operations, offering greater precision and energy efficiency.

- Hybrid Injection Molding Machines: Combine hydraulic and electric technologies to leverage the advantages of both systems.

When exploring options, Injection Molding Machine manufacturers provide comprehensive insights into the available technology and its benefits.

Advantages of Electric Injection Molding Machines

Electric injection molding machines have gained popularity due to their numerous advantages over traditional hydraulic machines. These benefits are critical for manufacturers aiming for sustainability and cost-effectiveness.

Energy Efficiency and Cost Savings

One of the most significant advantages of electric injection molding machines is their energy efficiency. Unlike hydraulic machines, which consume energy continuously to maintain pressure, electric machines only use power when needed. This can lead to substantial savings on electricity costs, particularly in high-volume production settings.

Precision and Quality Control in Production

Electric machines offer enhanced precision in both positioning and pressure control. This accuracy results in higher quality products with fewer defects and decreased scrap rates. The discrete intelligent drive used in many electric models provides rapid feedback and adjustments, ensuring consistent output quality.

Environmental Benefits of Electric Machines

As industries increasingly focus on reducing their carbon footprint, electric injection molding machines stand out due to their lower energy consumption and reduced hydraulic fluid usage. These machines also limit the risk of oil leaks, contributing to a cleaner working environment and less pollution.

Comparing Different Injection Molding Machine Series

To cater to various manufacturing needs, different series of injection molding machines offer unique features and capabilities.

TEII Series: All Electric Injection Molding Machines

The TEII series represents a state-of-the-art line of all-electric injection molding machines. With tonnages ranging from 90T to 460T, these machines utilize high-rigidity templates and a modular design that can adapt to diverse working conditions. The humanized interactive interface facilitates easy operation, making it suitable for high-precision applications.

TMII Series: Servo-Driven Solutions

Designed to integrate multiple devices through a single control interface, the TMII series servo-driven machines (90T to 470T) enhance productivity. Their automatic compensation for mold opening positions and real-time feedback mechanisms allow for seamless operation, making them ideal for complex mold designs and intricate product formations.

TH Series: Direct Press Type Machines

The TH Series, available in small, medium, and large configurations (130T to 2800T), employs a two-plate direct pressure center clamping structure. This provides a significant mold opening stroke, meeting the demands for the production of large, deep-cavity parts while also being compatible with automated part-picking systems.

Best Practices for Implementing Injection Molding Technology

Implementing an injection molding solution requires careful planning and execution. Here are some best practices to guide manufacturers in this endeavor.

Choosing the Right Machine for Your Production Needs

Selecting the appropriate injection molding machine is fundamental to achieving efficiency. Consider production volume, product complexity, and material types when making your decision. Electric machines are excellent for precision-driven operations, while hydraulic machines might serve better for high pressural applications.

Integration with Robotics and Automation

To maximize productivity, integrating injection molding machines with robotic systems can significantly enhance operational efficiency. Automation in part handling and packaging not only reduces labor costs but also speeds up the production cycle.

Maintenance Tips for Optimal Performance

Regular maintenance is crucial for ensuring the longevity and performance of injection molding machines. Schedule routine inspections, clean the machinery, and replace worn parts promptly to prevent production downtime and ensure consistent quality.

Future Trends in Injection Molding Machines for 2025

The injection molding industry is on the cusp of significant evolution driven by technological advancements and changing market demands. Here are some anticipated trends for 2025.

Emerging Technologies and Innovations

As Industry 4.0 becomes the norm, injection molding machines will increasingly feature smart technologies, including IoT connectivity for enhanced monitoring and predictive maintenance. The integration of AI will allow for better process optimization, ensuring higher throughput with less waste.

Industry Predictions and Insights

Experts predict that the demand for electric and hybrid machines will continue to rise, particularly for applications requiring high accuracy and minimal environmental impact. Manufacturers that adapt to these advancements will likely gain a competitive edge in the market.

Impact of Automation on Injection Molding Processes

Automation is set to redefine manufacturing. Enhanced integration of AI and robotics within the injection molding process promises to increase production rates and reduce costs. Companies that embrace such innovations will be better positioned to respond to market demands swiftly.